The project

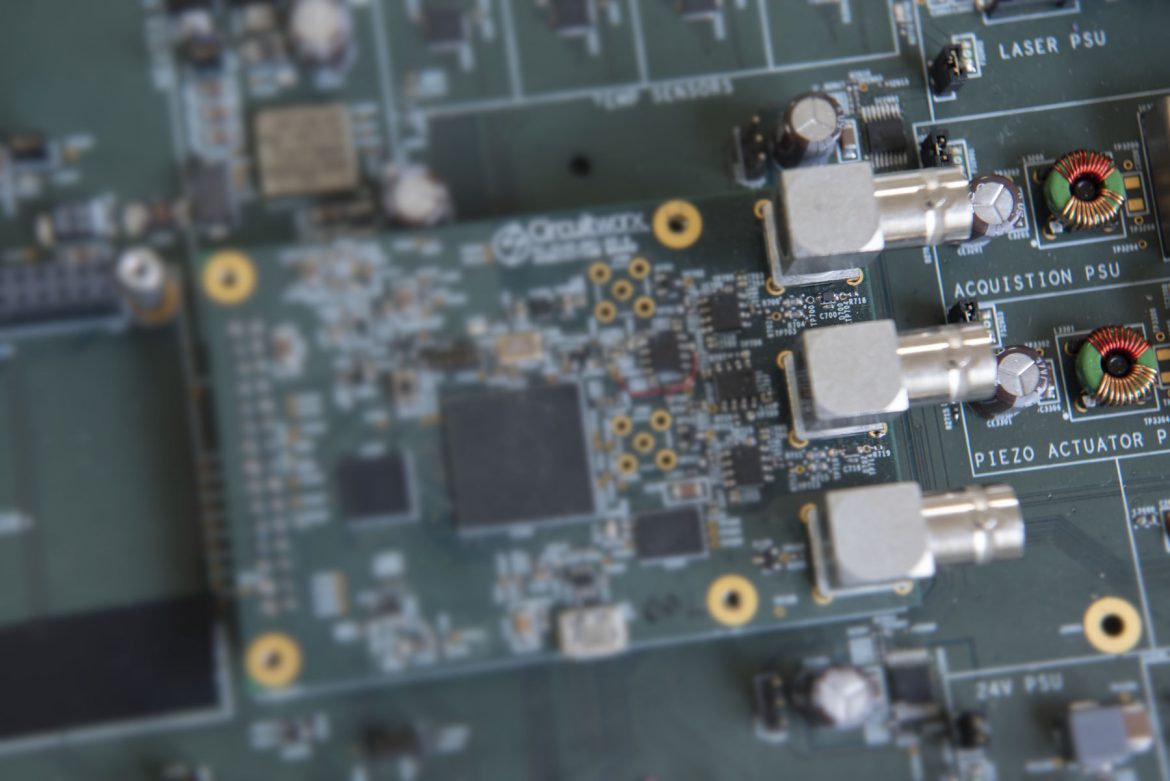

Working within a tight timescale, we designed and built a complicated control board with associated embedded firmware to interface to our client’s prototype scientific instrument for sensing molecule concentrations in liquids. This enabled our client to produce an integrated system that they could use to test and demonstrate their unique sensing technology.

The challenge

Our client had already developed a lab-based prototype precision scientific instrument based on their proprietary technology. The next step in their roadmap was to develop this into a kiosk-based system. With their scientific expertise and know-how heavily invested in their unique sensing technology, they needed some extra support with developing the control and data acquisition electronics to drive the system.

Timescales were tight on this project, but as our client had already undertaken the initial stages of R&D themselves we were able to kick off in Phase 3 of our engineering development process. Our flexible ‘can do’ attitude was helpful to this particular client and they were prepared to accept the increased project risk of this approach.

Having mapped out the top-level system architecture during the initial discussions and proposal, we then started to add detail to this and compile a written requirement specification for the electronic circuit and the microcontroller interface. This specification detailed the exact interaction with the plethora of sensors and actuators in the system, enabling us to ensure that we had fully understood the client’s requirements and that everyone was clear about the expected functionality of the first engineering prototype board.

Next we developed the embedded software for the NXP LPC microcontroller at the heart of the system, and the detailed circuit design, schematic entry and PCB layout. The step-repeat feature of our CAD software was really useful for this project, and even though the PCB was large and complex we were still able to meet the target deadline.

We built and tested three engineering prototype PCB assemblies, verified the design and delivered them to the client so they could validate the functionality within their own system. And as is standard with our projects, we also delivered the full set of manufacturing files including schematics, PCB layout files (gerbers and step file), firmware and Bill of Materials, so they have full control over their design in the future.

Having successfully completed this development task, our client asked us to carry out some further work designing a data acquisition board and writing software for a Raspberry Pi Compute module to extend the functionality of the system with a Node.JS web interface. We were delighted to help!

The CircuitWorx touch

It’s frustrating when you get hold of complicated technology that you have no idea how to use, and we don’t like leaving our clients frustrated! This was a complex board with many different interfaces, so we made sure we also took the time out to write a detailed engineering user manual so our client could ‘hit the ground running’ with their system integration phase.